How to make the industry of valve lathe processing rise

In the past ten years, with the entry of foreign electronics, communication, optics and other industries into China, the mechanical processing industry is developing in a light, thin, short and small direction. The demand for accessories such as mobile phones and computer industry is large, and the processing precision is high, prompting machinery. Processing has a greater demand for turning automation, so the automatic lathe processing industry has created an effect. Equipped with several automatic lathes, it plays an important role in improving the processing precision of machining companies, reducing processing costs and improving economic efficiency.

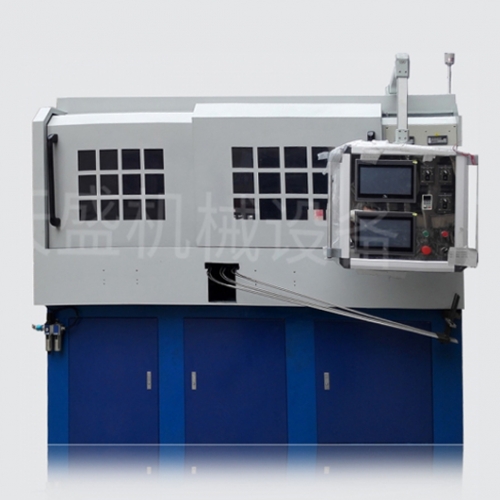

Unlike general lathes, valve lathes are cam-type lathes that are controlled by cam drives to achieve automated operation. The development of cam-type automatic lathes has a long history. From the beginning of the production of watch parts by Swiss machine, it has gradually developed into a knife-cutting machine. Japan has also played a big role in the development of automatic lathes. The automatic lathe has an indelible contribution to the improvement of machining accuracy. Since the manufacture of automatic lathes in Taiwan, Taiwan's mechanical processing industry has developed rapidly. In the past ten years, Taiwan's automatic lathe manufacturing industry has targeted the machinery processing industry in the mainland and transferred manufacturing bases to the mainland. Due to the reduction of manufacturing costs and the improvement of manufacturing quality, automatic lathes have sprung up in the southeastern part of China. It is.

At present, many mechanical processing companies in mainland China are still using table instrument valve lathes to process mechanical parts. Although the instrument lathe is inexpensive, it requires a lot of manpower to operate. Its production capacity is low and the processing precision is not high. For the processing of large quantities of small parts, the processing efficiency is not high, the processing precision is not high, and the labor cost is high. The benefits of the company are naturally not high.

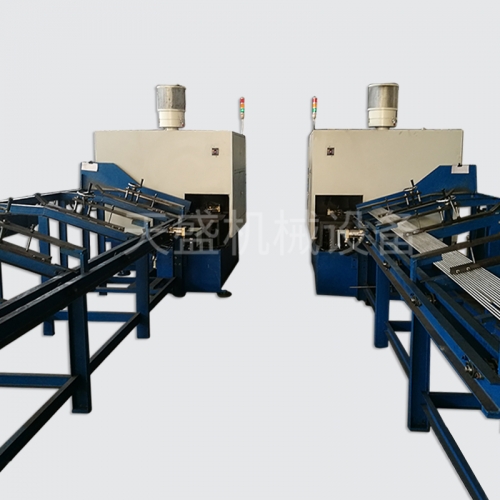

As a small-sized machining machine, automatic valve lathes are highly automated compared to table-top lathes. For example, when processing small copper parts, an operator can operate several automatic lathes at the same time, which can reach a long time. Unmanned operation. The automatic lathe can produce several times the capacity per minute of the table instrument lathe, which is suitable for the processing of small parts.

At present, many mechanical processing enterprises have recognized this problem and are gradually adopting such automatic valve lathes. The automatic lathe processing industry is emerging, which is an effective choice to reduce production costs, improve processing quality and enhance the competitiveness of the enterprise market.

The address of this article:http://bjdrhh.com/en/news/381.html

Key word:氣門磨床,氣門車床,氣門設(shè)備

Recently browse:

Related products:

Related news:

- The steps and methods of valve machine fault handling are nothing more than

- What adjusts the clearance of the valve lathe?

- Learn about the independent entry and exit of the valve lathe system

- Talk about the special equipment for the valve starting and starting the valve

- Tiansheng Xiaobian explains to you the classification of engine variable valve equipment intake

- So how should the principle and function of the valve device be understood?

- Tell me more about how the valve lathe controls the operation.

- Main features of welding of rod end drilling machine for valve equipment

- Safety precautions for using valve lathes

- What are the advantages of an automatic valve lathe as a guide feed thrust?